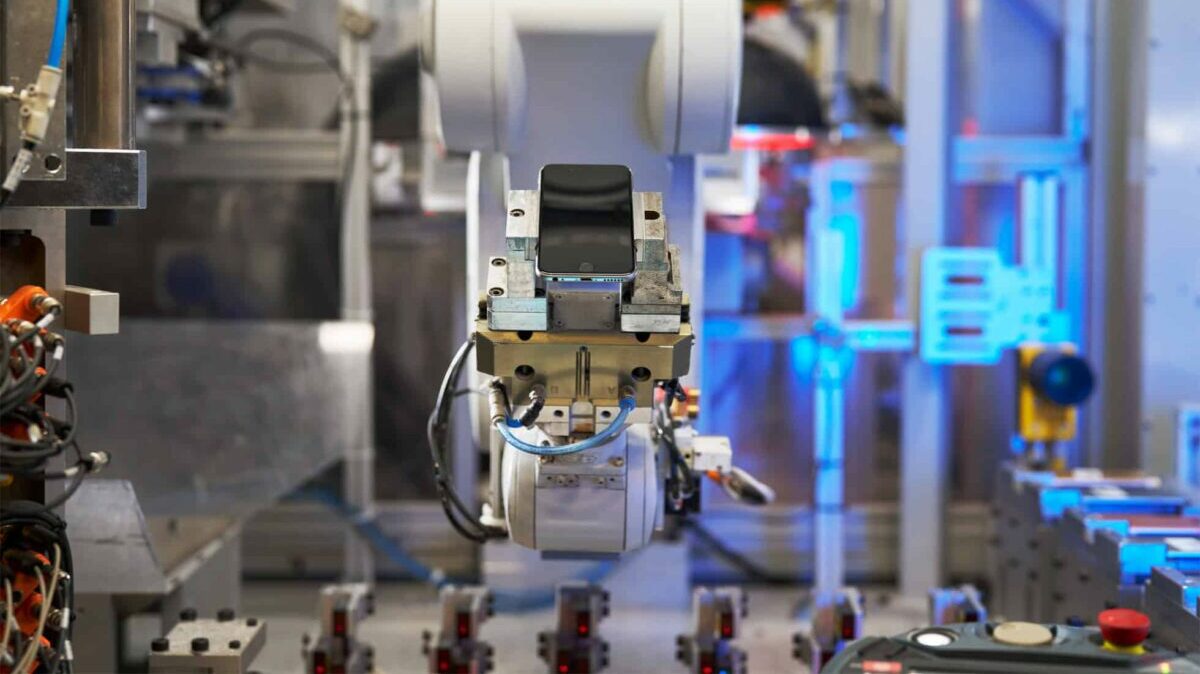

Apple is significantly ramping up automation across its global supply chain, with a new mandate that suppliers adopt robotics in their manufacturing processes. This represents a major policy shift, moving beyond encouragement and into strict requirements that directly affect Apple’s production partners. The strategy is designed to reduce reliance on manual labor, improve consistency across facilities, and prepare Apple’s supply chain for a more diversified future.

According to DigiTimes, Apple has now made robotics and automation a prerequisite for awarding manufacturing contracts across its key product lines. The requirement covers the iPhone, iPad, Mac, and Apple Watch, which means nearly every supplier tied to Apple’s core hardware business must make significant changes. Unlike past years, when Apple often provided financial assistance for new equipment and tooling, suppliers are now expected to fund the automation themselves. The change has created financial pressure for many manufacturers, who must manage steep upfront costs while also handling operational disruptions during the transition.

The short-term strain on supplier profitability highlights how disruptive the automation mandate has already become. Integrating robotics requires heavy investment not only in machines but also in training, system design, and workflow adjustments. Some suppliers are reportedly struggling to balance these expenses while maintaining production volumes. Still, Apple appears to be prioritizing long-term efficiency gains, believing that robotics will ultimately reduce costs and make its supply chain more resilient to political or economic uncertainty.

Apple is not leaving its suppliers entirely unsupported. The company continues to provide assistance in areas that align with its environmental targets. As part of its 2030 pledge to reach carbon neutrality across its entire supply chain, Apple is helping partners upgrade to more energy-efficient machinery and sustainable materials. This shows a dual-track strategy: while financial support for robotics has been withdrawn, Apple is still willing to invest where it strengthens its green commitments and public image.

The broader benefits Apple is seeking from this shift include more standardized inspections, reduced vulnerability to labor shortages, and greater control over product uniformity when production is split across multiple countries. Robotics also allows Apple to onboard new suppliers more quickly, since automated processes can be replicated with fewer variables compared to human labor. This is especially critical as Apple continues to diversify beyond China into regions like India and Southeast Asia.

Industry analysts suggest that while suppliers face immediate challenges, the long-term implications may be positive. Automated production lines can operate continuously, deliver higher precision, and reduce risks tied to workforce availability. For Apple, that translates into steadier product launches and less exposure to disruptions that could affect iPhone and Mac production. However, the societal impact of this push remains controversial, with critics warning about potential job losses and increased inequality as manual factory work declines.

This aggressive move underscores Apple’s determination to reshape its supply chain around efficiency, sustainability, and reduced human dependency. Whether suppliers can shoulder the financial burden fast enough remains to be seen, but Apple’s direction is now clear: robotics and automation are no longer optional, they are the new standard for working with the company.