TSMC has officially unveiled its 1.4-nanometer A14 chip process, set to power future Apple Silicon starting in 2028. Confirmed during the company’s North America Technology Symposium, the A14 process represents the next major evolution in semiconductor manufacturing and is expected to play a pivotal role in Apple’s future A-series and M-series chip designs.

TSMC’s A14 will succeed the N2 process, which is scheduled to enter volume production in late 2025 and expected to power the iPhone 17 Pro. The company says A14 will deliver a 15% performance improvement at the same power level or reduce power consumption by up to 30% for the same performance, alongside a 20% boost in logic density.

Apple, a primary client of TSMC and typically the first to adopt its most advanced manufacturing technologies, is expected to implement the A14 process in its 2028 iPhone lineup—likely the iPhone 19 Pro—possibly in a chip dubbed the A21 Pro. Despite the naming overlap with Apple’s 2020 A14 Bionic chip, the A14 designation here refers to TSMC’s angstrom-based naming convention for sub-2nm nodes, marking a significant transition in the way chip generations are labeled. This shift reflects the move from N-prefixed processes to A-prefixed ones, with A14 representing the 14-angstrom—or 1.4nm—generation.

The current trajectory of Apple Silicon has been heavily influenced by TSMC’s process innovations. From the 5nm A14 Bionic to the 3nm A17 Pro, Apple has consistently reaped the benefits of leading-edge fabrication. The upcoming 2nm node, which Apple is expected to use for the A19 Pro chip in 2026, will again boost performance, as seen previously when the A17 Pro introduced a 20% faster GPU and a Neural Engine that doubled in speed over its predecessor. With TSMC’s A14 node, Apple could potentially see chips that are up to 30% faster and 60% more efficient than current 3nm silicon.

In addition to performance gains, TSMC’s A14 process is tailored to enhance AI capabilities across devices. The new node is optimized for the kind of on-device intelligence Apple is increasingly integrating into its hardware, from real-time photo and video processing to advanced machine learning in iOS and macOS.

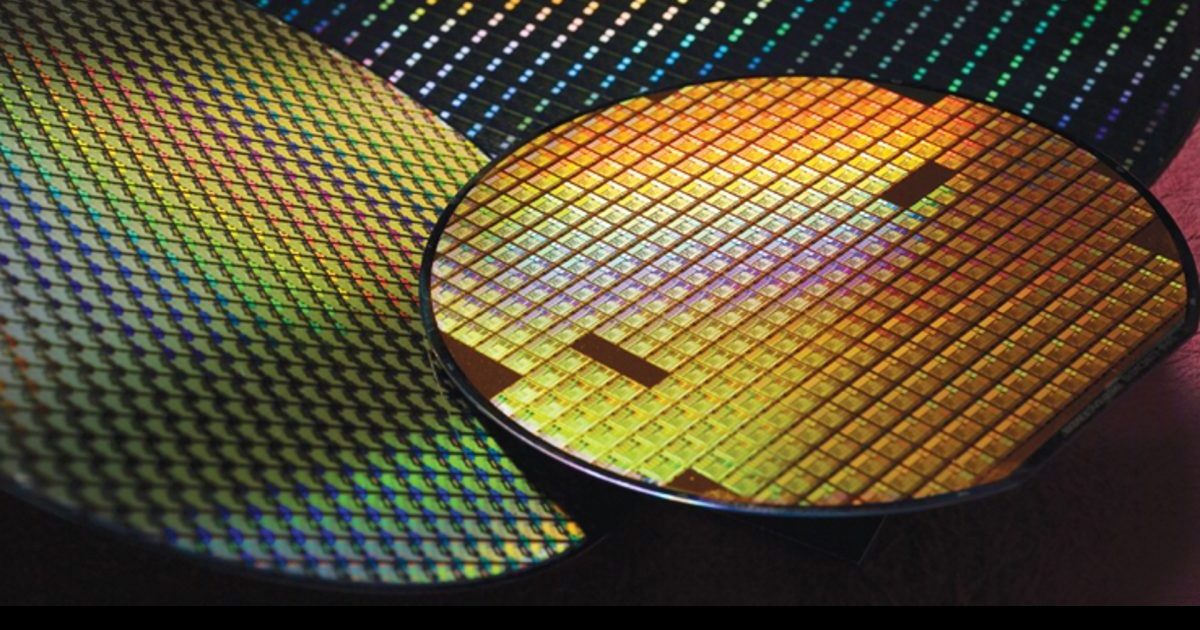

Production capacity for new nodes is always a premium, and Apple’s early access to TSMC’s latest technology often results in exclusive deals. This trend is likely to continue with the A14 process, as Apple typically secures the majority—if not all—of TSMC’s cutting-edge wafer output in the initial launch year. There’s even speculation that Apple may reserve the A14 process for exclusive use in its A22 or A23 chips, depending on production timelines and competitive demands from other clients like Intel and AMD.

While TSMC will begin manufacturing the A14 process in 2028, it is also preparing an intermediary A16 node, a 1.6nm process featuring a new backside power delivery system that simplifies chip design and improves energy efficiency. This node will bridge the gap between the 2nm and 1.4nm generations, providing incremental gains before the next major jump. Meanwhile, TSMC’s only serious competitor in this space, Samsung, has reportedly paused its own 1.4nm plans, leaving TSMC in a strong position to dominate the sub-2nm race through the end of the decade.