Apple’s M1 and A-series chipmaker TSMC is on the road to carry out a risk production of 3nm chips later this year. A 3nm process will be used for future iPhones, although the scenario is highly unlikely until 2023.

Risk production is a term used when a foundry has carried out purely internal testing, and sincerely believes that it is now ready to try the process on customer designs to check whether those can be successfully manufactured or not.

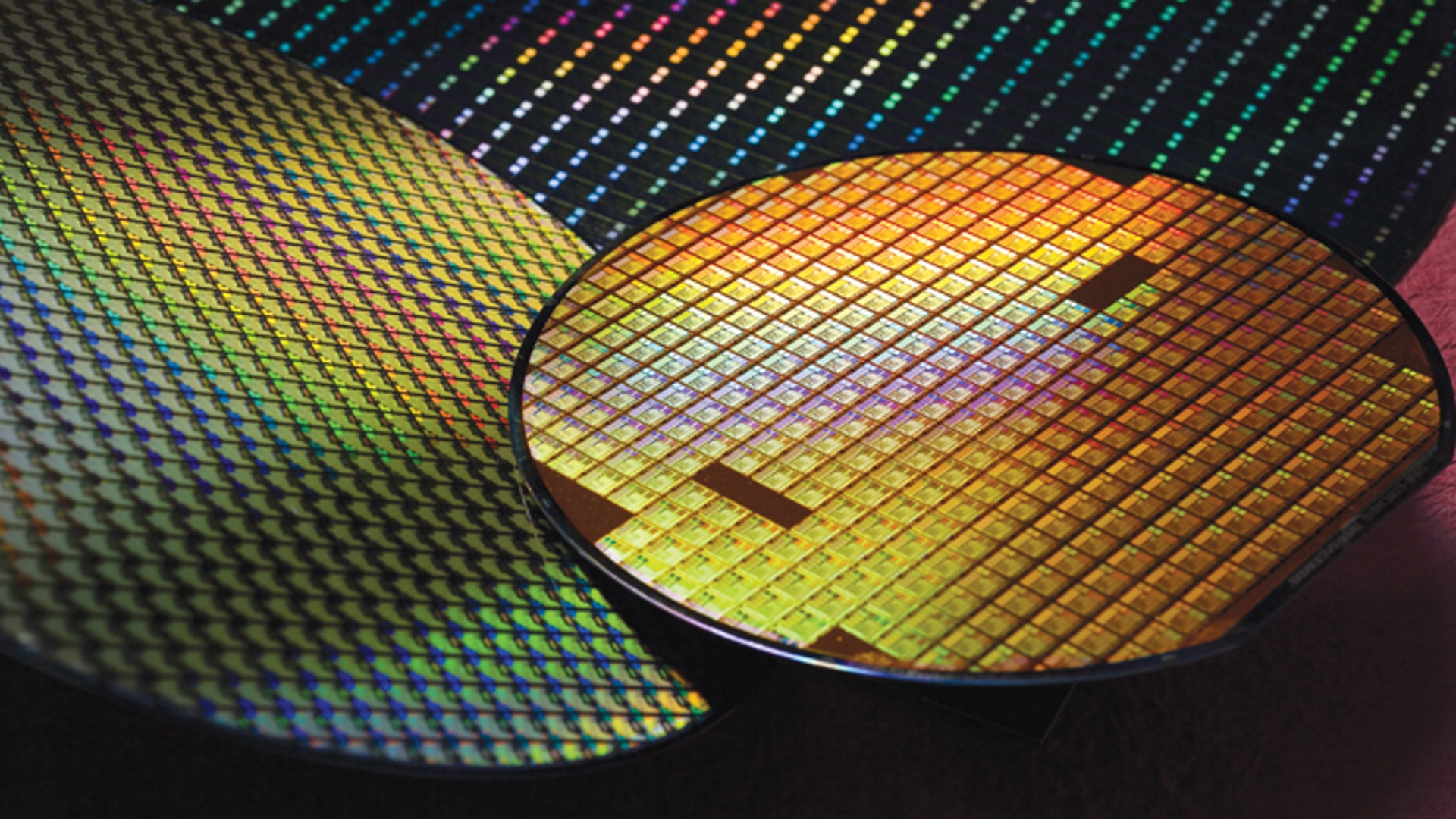

Apple chipmaking partner TSMC will start production of 3nm chips this year

A report by Digitimes shows that TSMC expects to be ready for volume production by the second half of 2022. The chances of seeing 3nm chips in the 2022 iPhone are quite slim, so it is expected that this new process will be used for 2023 models.

TSMC is on track to move 3nm process technology to risk production in 2021 followed by volume production in the second half of 2022, according to the pure-play foundry.

“Our N3 technology development is on track with good progress,” said TSMC CEO CC Wei at the company’s earnings conference call on January 14. “We are seeing a much higher level of customer engagement for both HPC and smartphone application at N3 as compared with N5 and N7 at a similar stage.”

![]()

TSMC has been miniaturizing its process over the years, from a 16nm A10 chip in iPhone 7 models to a 5nm A14 chip in iPhone 12 models. Apple will most likely use a 5nm A15 chip for the 2021 iPhones, and TrendForce expects that it is highly unlikely that the A16 chips in 2022 iPhones will be manufactured based on TSMC’s future 4nm process, hinting that the new 3nm technology will most likely be utilized for a potential A17 chip and potentially other future Apple silicon Macs if the company follows its previous pattern.

The 3nm process yields 30 percent and 15 percent power consumption and performance improvements over the 5nm process. TSMC triggered a global chip stocky rally on Thursday, after outlining plans to pour as much as $28 billion into capital spending this year – more than half the company’s projected revenue for 2021 – reported by Bloomberg.

The A15 chip in Apple’s 2021 iPhones will stick with a 5nm process, but will move to an enhanced ‘5nm+’ version […] TSMC refers to 5nm+ as N5P, and describes it as a performance-enhanced version which will combine greater power with improved power efficiency to improve battery-life (or, as might be more likely with Apple, permit smaller-capacity batteries).

The A16 chip is expected to use what’s known as a process shrink, or die shrink, version of the 5nm+ version. Rather than being an entirely new chip process, this is a way to shrink the size of an existing chip without any major changes to its design. This gives more chips per wafer, which reduces manufacturing costs

The reduced size offers performance benefits, however, as the smaller chip generates less heat and can operate at full speed for longer before thermal throttling is required.

TSMC also plans to build and operate an advanced semiconductor factory in Arizona, with construction planned to start in 2021 and production targeting to begin in 2024. TSMC estimates that its total spending on the 3nm project will approximately be $12 billion from 2021 to 2029, along with the facility expected to create over 1600 high-tech professional jobs directly.

Read Also:

2 comments