Apple senior vice president of hardware technologies, Johny Srouji sat down with The Wall Street Journal for a rare interview to discuss the development of the M1 (first-generation Apple Silicon) during the COVID-19 pandemic.

Srouji joined Apple in 2008, to lead the development of chips for the iPhone, in 2015 he became part of the company’s senior executives board and since then, his team has worked on the development of chips for all Apple products. Now, leading a global team of thousands of engineers, Srouji and his team exercise a substantial influence and significance in product development at the company.

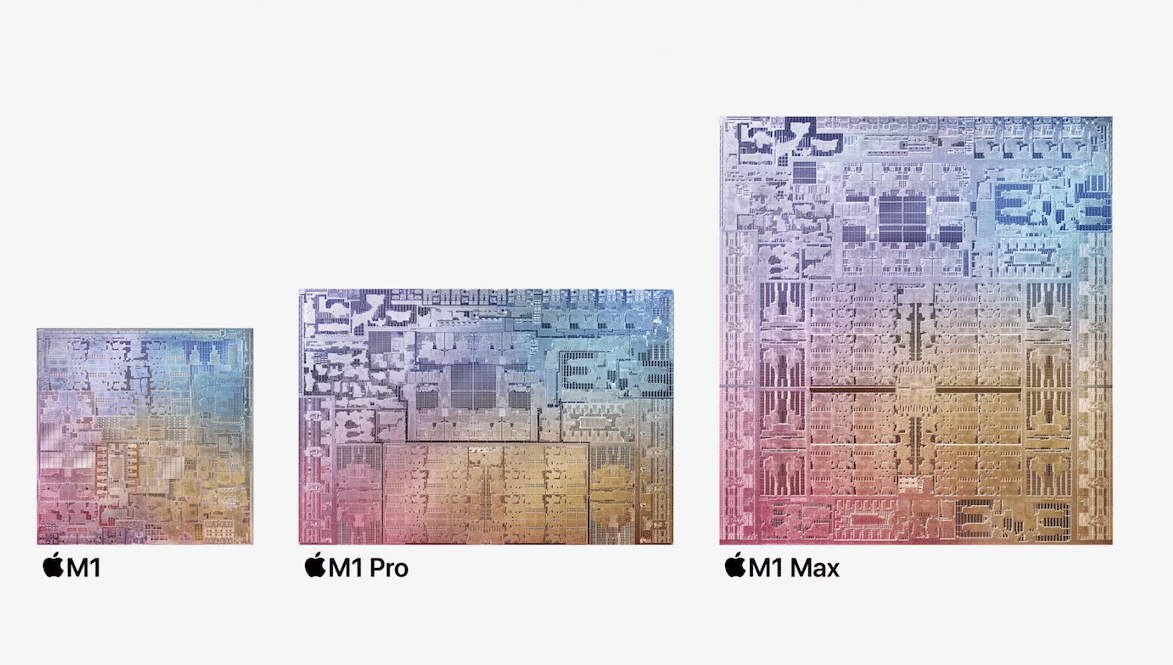

In 2020, the company launched its first M1 chip which marked the transition from Intel processors to Apple Silicon for Macs. Since then, Macs powered by M1 chips have received great reviews for their fast performance and incredible power efficiency. For the first time, we are hearing from Srouji about how the M1 chip was developed in the midst of the global health crisis and its respective travel restrictions.

Srouji set up cameras throughout the labs during the M1 Apple Silicon validation process

Srouji recalls that when the COVID-19 pandemic broke out, the M1 chip was in the validation process and it was able to navigate through that because of his life’s lesson to be flexible and adaptive to tackle unforeseen hurdles.

“What I learned in life: You think through all of the things you can control and then you have to be flexible and adaptive and strong enough to navigate when things don’t go to plan,” Mr. Srouji, Apple senior vice president of hardware technologies, said in a rare interview. “Covid was one for example.”

Srouji designed a new testing process by asking the team to set up cameras throughout the labs for engineers to inspect the chips remotely which it was trained to manage prior to the health crisis.

It was the kind of change that would have once been hard to imagine from Apple, where secrecy and control are paramount.

In part, the operation was able to pivot so seamlessly because Mr. Srouji’s team is spread out around the globe, already accustomed to conducting business through video calls and working across time zones as they coordinated work in far-flung locations such as San Diego and Munich, Germany, two places where the company is investing billions to expand into designing chips for its wireless-technology capabilities.

He furthermore explained that M1 was optimized for new Macs with the collaboration between the hardware engineers and the company’s software engineering team.

As Apple’s hardware engineers sought to design the chips as efficiently as possible for its particular needs, the company’s software designers tuned the computers to favor the specifications it most desired, such as smooth videogame graphics.

“First and foremost, if we do this, can we deliver better products?” Mr. Srouji said of the debate. “That’s the No. 1 question. It’s not about the chip. Apple is not a chip company.”

And more importantly, Srouji said that his time has not peaked, and it’s not a one-time effort. They are going to build great products year after year.

“I don’t do it once and call it a day,” Mr. Srouji said. “It is year after year after year. That’s a huge effort.”